PLASTIC INJECTION MOULD

is a manufacturing process that involves injecting molten plastic into a mold cavity. It is commonly used to produce various plastic products with high precision, complexity, and consistency.

PLASTIC INJECTION MOULD

Standard Mould Components & Runnerless Moulding Systems

LBSB has worked closely through the years with D-M-E, the world’s leading manufacturer of basic tooling and supplies for the plastic and die casting industries. D-M-E moulds have made a name for themselves in the market with its variety of injection moulding applications.

Ejector Pins

Standard ejector pins and core pins are made of thermal-shock-resisting hot work die steel [AISI-H-13]. Using this high-strength steel the physical properties are able to withstand the continuous friction and thermal and mechanical stresses of plastics moulding and die-casting.

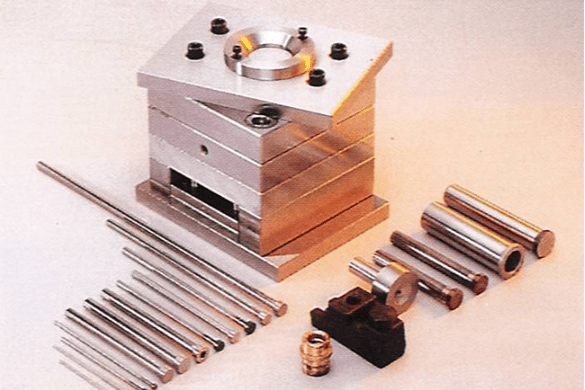

Mould

Custom-built mould base, Affordable, Quality, Speedy Delivery.

Standard mould base, Custom built mould base, Ejector Pins, Leader Pins & Bushing, Core Pins, Full Hardened Pins, Nitrided Ejector Pins.

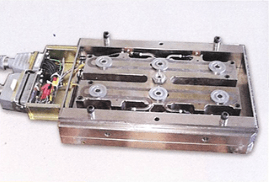

Hot half of a Hot Runner Mould

D-M-E Runnerless Moulding Systems

Cool one

Hot one

Valve gate system

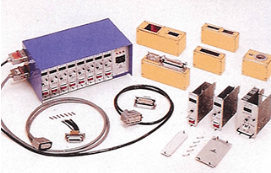

D-M-E Temperature Controller & Accessories